I had the opportunity to acquire one of the above second hand and was unable to resist the temptation, being a great fan of Veritas quality and design innovation. For those not yet affected by the (as yet uncurable) toolie virus, the shoulder plane differs from the rebate plane by having a low angle 12 degree bed to cut end grain cleanly on tenon shoulders, secret mitre dovetails and other similar everyday tasks.

For this application it would be better to have a shallow honing angle to further improve performance and, if buying new, I would have specified a traditional A1 carbon steel blade to hold a fine edge. My example came with a high speed steel A2 blade, which will hold it's edge longer, but may need to be honed slightly higher to avoid crumbling of the edge. This is particularly important as the plane is targetted at end grain.

There was a bit of a drama on purchasing when the original owner announced there was an "issue" with these planes in that the bed distorted when the blade clamp was tightened. I took this up with Rob Lee, the MD of Veritas, and he assured me that there was no issue but clearly the effect of tightening the clamp would be to cause some movement, as with any loaded beam, but this was not a significant issue. In any case, it was not necessary to tighten the clamp more than enough to retain the blade.

Fortunately the plane arrived in good condition and had clearly seen little use.

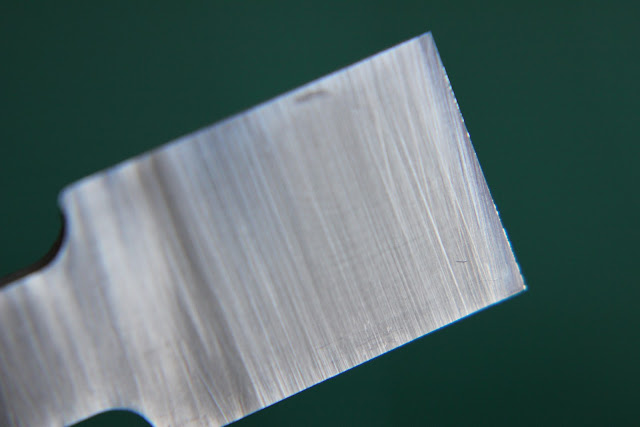

The blade had clearly had some difficulty in it's early life and the final polishing of the back, normally a quick operation on Veritas tools owing to the fine pre-lapping, had resulted in a slightly rounded over edge, possibly from a slightly hollowed stone.

There was also some evidence of the aforementioned crumbling with an uneven hone on the top edge.

Working quickly through the grades from 1000 to 6000 waterstones quickly removed the marks from the back. I decided to re-grind the upper bevel on the Tomek to remove any soft edge and even out the primary bevel before final honing.

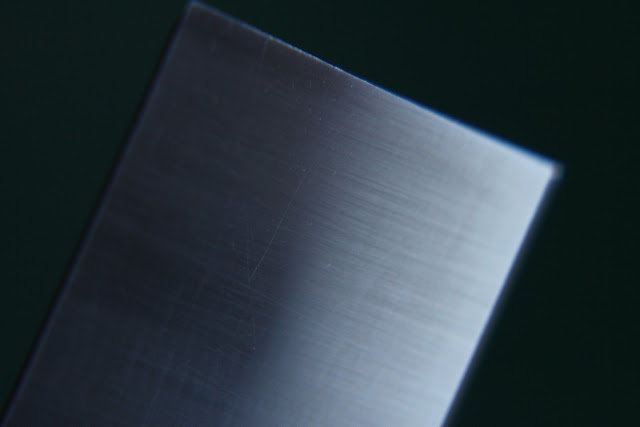

A final finish on the 8000 Cerax finished the job nicely.

The upper bevel after re grinding to 25 degrees and the addition of a small bevel removed the original rounding over and produced a fine edge at 30 degrees.

A test on a small piece of American White Oak confirmed the excellence of the design. It was much easier to hold and control than the traditional Stanley/Record and produced a very fine and even shaving with minimal setting up. The adjustable mouth is another benefit over the Stanley and more important on long grain work like this, rather than end grain.

Ready for action. All I need is the time for some furniture making.

I have not mentioned the blade side guide grub screws or the Norris type blade adjuster as these are less important in a shoulder plane where the blade needs to be moved from side to side according to the direction of the grain. Clearly you really need a pair of them! Having said that they should probably be set so that they define the limits at each side with the skew adjuster used to even the shaving across the width.

This is truly excellent tool with all the benefits of Veritas development and, whilst it may not be something most woodworkers might use every day, is invaluable when the need arises. The overall quality is stunning and it is a beautiful tool to own and use.

For this application it would be better to have a shallow honing angle to further improve performance and, if buying new, I would have specified a traditional A1 carbon steel blade to hold a fine edge. My example came with a high speed steel A2 blade, which will hold it's edge longer, but may need to be honed slightly higher to avoid crumbling of the edge. This is particularly important as the plane is targetted at end grain.

There was a bit of a drama on purchasing when the original owner announced there was an "issue" with these planes in that the bed distorted when the blade clamp was tightened. I took this up with Rob Lee, the MD of Veritas, and he assured me that there was no issue but clearly the effect of tightening the clamp would be to cause some movement, as with any loaded beam, but this was not a significant issue. In any case, it was not necessary to tighten the clamp more than enough to retain the blade.

Fortunately the plane arrived in good condition and had clearly seen little use.

The blade had clearly had some difficulty in it's early life and the final polishing of the back, normally a quick operation on Veritas tools owing to the fine pre-lapping, had resulted in a slightly rounded over edge, possibly from a slightly hollowed stone.

There was also some evidence of the aforementioned crumbling with an uneven hone on the top edge.

Working quickly through the grades from 1000 to 6000 waterstones quickly removed the marks from the back. I decided to re-grind the upper bevel on the Tomek to remove any soft edge and even out the primary bevel before final honing.

A final finish on the 8000 Cerax finished the job nicely.

The upper bevel after re grinding to 25 degrees and the addition of a small bevel removed the original rounding over and produced a fine edge at 30 degrees.

A test on a small piece of American White Oak confirmed the excellence of the design. It was much easier to hold and control than the traditional Stanley/Record and produced a very fine and even shaving with minimal setting up. The adjustable mouth is another benefit over the Stanley and more important on long grain work like this, rather than end grain.

Ready for action. All I need is the time for some furniture making.

I have not mentioned the blade side guide grub screws or the Norris type blade adjuster as these are less important in a shoulder plane where the blade needs to be moved from side to side according to the direction of the grain. Clearly you really need a pair of them! Having said that they should probably be set so that they define the limits at each side with the skew adjuster used to even the shaving across the width.

This is truly excellent tool with all the benefits of Veritas development and, whilst it may not be something most woodworkers might use every day, is invaluable when the need arises. The overall quality is stunning and it is a beautiful tool to own and use.

2 comments:

I`m sure you`ll be very happy with the plane, they really are top quality. By the looks of things it doesn`t seem to have seen a deal of action if any judging by the lack of prep the blade had undergone.

Lookd like it was a good buy, Brian.

Cheers ;-)

Paul Chapman

Post a Comment